Legacy LogScope™ Testing

Legacy LogScope™ testing is still available, if required. It is only really useful on UUT with small GXY and small screen resolutions ie for VIFD™. LogScope allows the User to graphically track small resistance changes measured across any two test points in the UUT to aid in diagnosing which points in a node may be causing a lack of continuity, a shorting condition, or circuit intermittency. This would typically be carried out if a test point has exhibited intermittent faults and/or is showing as an anomaly in other tests, such as Intermittence Testing or Continuity Testing.

For instance, when continuity testing shows that there is a high resistance between two TPs, it is not known which of the two TP is really the cause of the problem. Using LogScope you can measure between any two connected points. Using this Click&Test™ facility, then allows the User to monitor the connectivity between these points as it is wiggled, tapped or otherwise stressed by the User. This will potentially help to isolate the problem at its root cause.

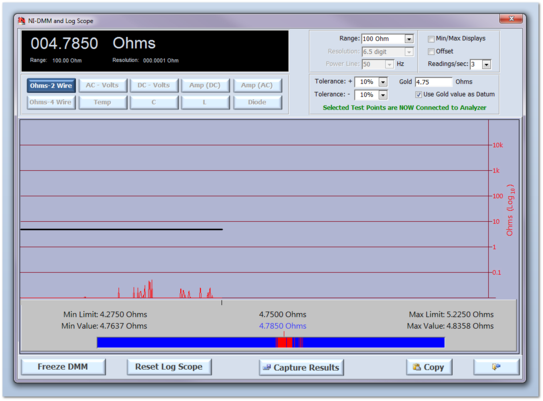

The LogScope function, within the testing environment, captures and then plots each measurement and the difference between the current and the previous measurement as logarithmic values on the screen.

The example above illustrates a test of a nominal 4.75W component being measured and the readings plotted in black in Log10. The trace in red shows the absolute difference between the previous and current readings to the Log10; the red line should be zero and would not have any spikes or plotted points above the baseline datum for a stable component/test point. Any deviation from the datum reading, positive or negative, is shown by the red spike line, and thus shows that this component/ test point is unstable.

For more information on LogScope, it features and the nomenclature, see Legacy LogScope™ Details.